As auto manufactures continue to build lighter weight vehicles the issue of collision repair is a factor. Lighter weight vehicles get better fuel economy and still maintain their safety but in the event of a fender bender, can those materials be repaired easily?

As structural materials become more advanced for the future automobile, will they be cost effective at the body shop?

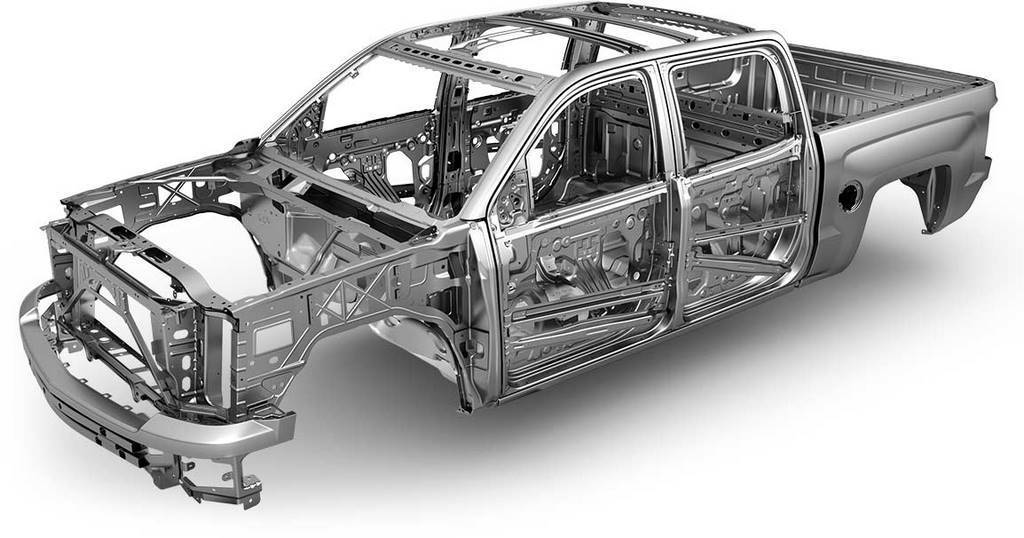

General Motors tackled this concern with the 2015 Chevrolet Silverado. The truck’s engineers incorporated several features assisting collision repair technicians should they see a next generation Silverado in their shop.

“When we design trucks, we don’t only consider what features our consumers demand from a full-size truck,” says Mark Szlachta, a GM Serviceability Design Engineer. “We also approach the process with our technician hat on.”

Here are 6 ways the 2015 Chevrolet Silverado lends itself to a more streamlined collision repair process.

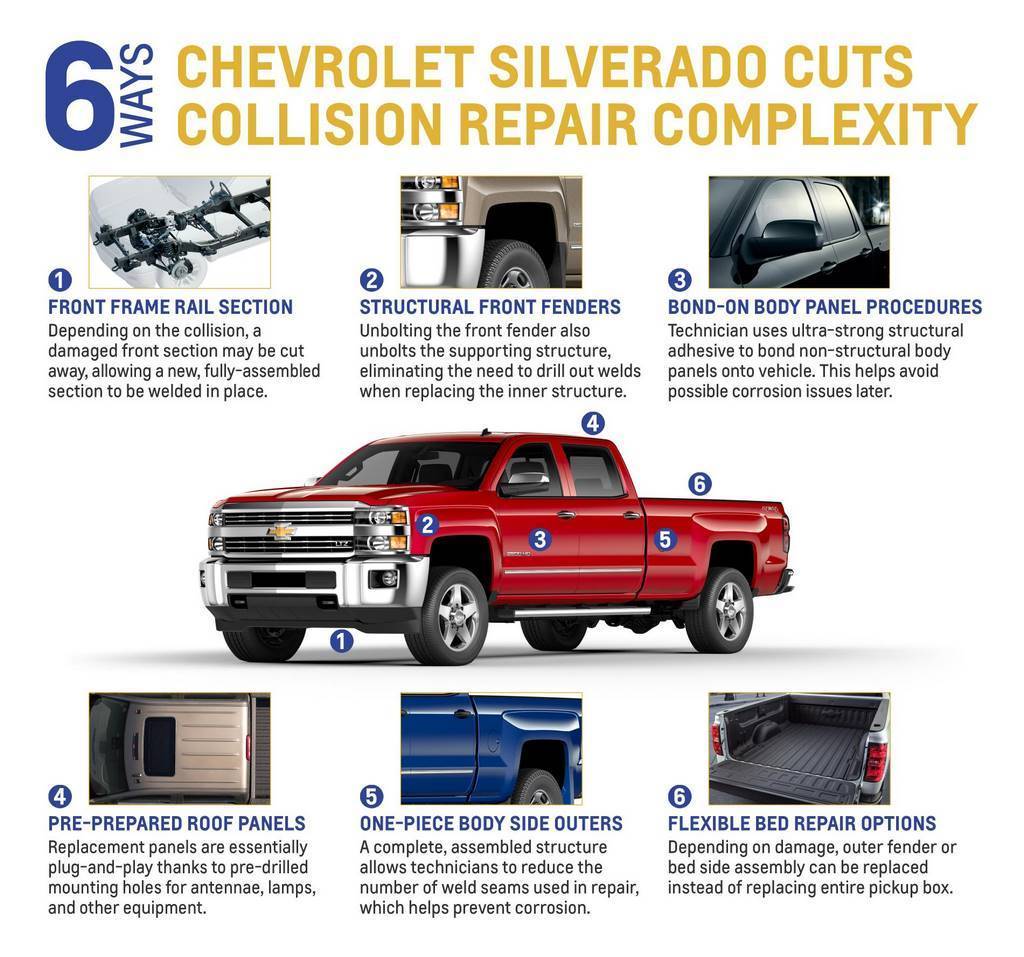

Front Frame Rail Section

Because of the way Silverado’s front frame rails are engineered, minor impacts don’t necessarily equate to substantial repair bills. Depending on the severity of the impact, technicians may be able to repair a leading section of the truck’s frame instead of replacing the entire chassis.

If so, the damaged section can be cleanly cut away at a specific location, and a new service section – shipped fully assembled – can be welded in place.

Structural Front Fenders

On many passenger vehicles, unbolting a damaged front fender removes only the outer skin, leaving behind additional structure welded to the cab. If that structure is damaged, technicians then need to drill out welds in order to remove the panel.

On the Silverado, the front fenders incorporate both outer sheet metal and the supporting inner structure, allowing simple unbolting of the entire assembly.

Bond-On Body Panel Procedures

When it comes to replacing non-structural body panels, including outer roof panels or outer door panels, technicians can use an ultra-strong structural adhesive to bond the panels onto the vehicle. This helps avoid welding and possible corrosion issues later while speeding the repair.

Pre-prepared Roof Panels

Technicians can get replacement panels that essentially plug-and-play, thanks to pre-installed studs and pre-drilled holes for accessories.

One-Piece Body Side Outers

If damage occurs to the outer panels of the cab, technicians can order a complete body side outer, shipped as a single, complete assembly, allowing technicians to cut out and replace only the damaged area instead of the entire assembly.

“Our goal is to only have weld seams where we absolutely need them,” Szlachta said.

Flexible Bed Repair Options

If the Silverado’s pickup bed or outer bedside should ever be significantly damaged, owners won’t necessarily need to purchase an new pickup box.

Depending on the damage, the outer bedside or the bedside assembly can be replaced from the bed floor out.

The simplicity for technicians in the body repair process will ultimately be passed onto the customer.

It’s one of the biggest benefits of the 2015 Chevrolet Silverado.

“We wanted to engineer a truck that is straightforward and cost-effective to repair,” Szlachta said.

– – –

Special Thanks: Tom Wilkinson – Trucks Manager, Silverado

Photos: Chevrolet

About Chevrolet: Founded in 1911, Chevrolet is one of the world’s largest automotive brands, with a presence in more than 115 countries. From the rugged Silverado to the iconic Corvette, performance, fuel efficiency, technology and safety remain cornerstones of the brand. Chevrolet resides in Detroit, Michigan under the General Motors namesake.