- Car Zero, created by Bentley Mulliner, is the first new Blower since 1930.

- Handcrafted from original drawings by in-house techs and British suppliers.

- An extensive testing and durability program is set to begin, including top speed runs.

Bentley has gone and done the most Bentley thing imaginable: They brought back the Blower. No, not a modern, updated version of the car that put them on the map, the “Blower” Bentley from the late 1920s. They’ve gone and remade the old Blower as a continuation car. This is a very cool move.

For those not in the know, cars like this are basically another production run – or a continuation of a production run – of a famous car from the past. The people best known for this are Shelby, who has made limited runs of the Cobra from the 1960s. Continuation cars are usually not something done by “respectable” car companies, especially car companies like, well, Bentley. But huzzah, someone must have slipped some tipple into Bentley’s tea because check this monster out.

Car Zero Emerges

It’s just like what the legendary Sir Henry ‘Tim’ Birkin raced at Le Mans in the late 1920s. And I mean just like the 90-year-old car. Bentley designed and hand-crafted nearly 2,000 parts and put in more than 40,000 hours of work before they were finished with what they call Car Zero, the prototype for the Blower Continuation Series.

The Blower Continuation Series is a limited production run of just 12 customer-specified cars. All have been pre-sold, so don’t even think of bothering your local dealer. Car Zero is just like the 12 that will find their way into the lucky hands of Bentley collectors.

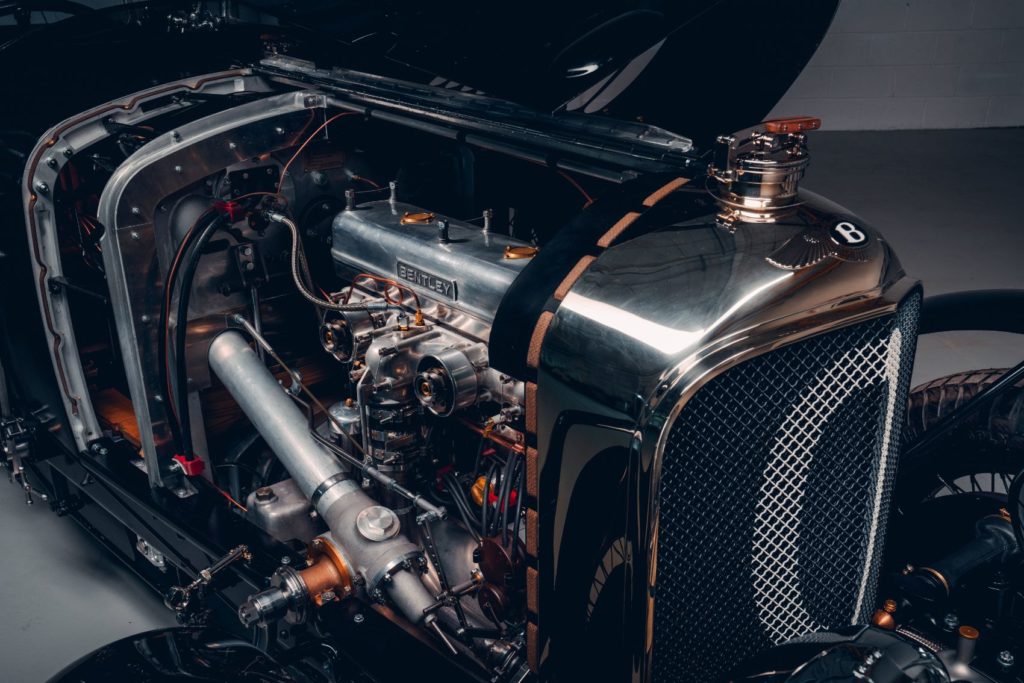

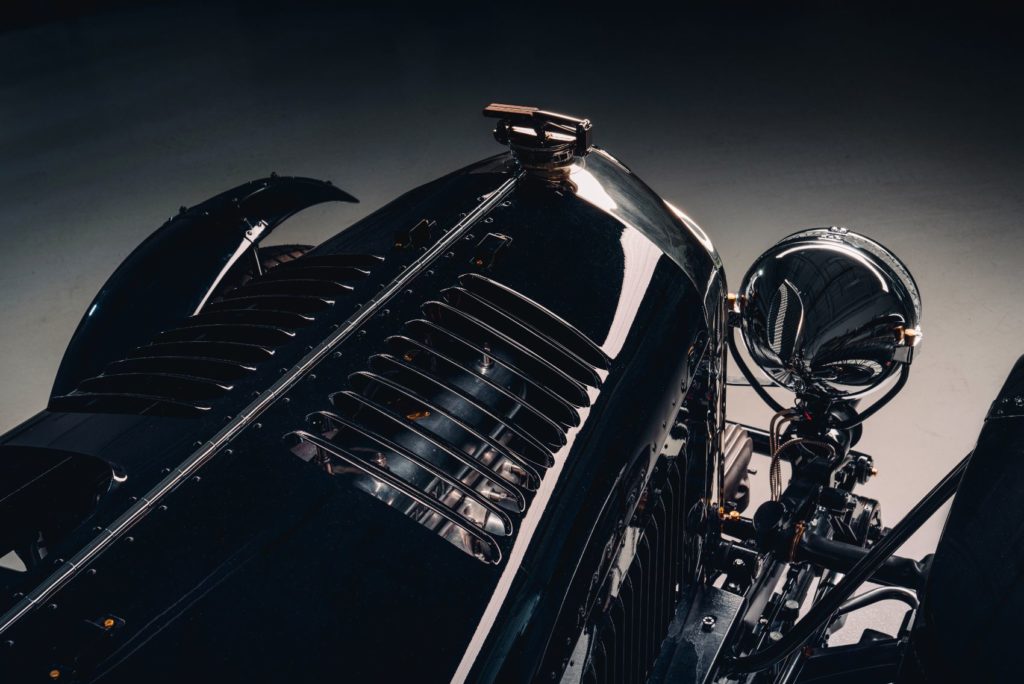

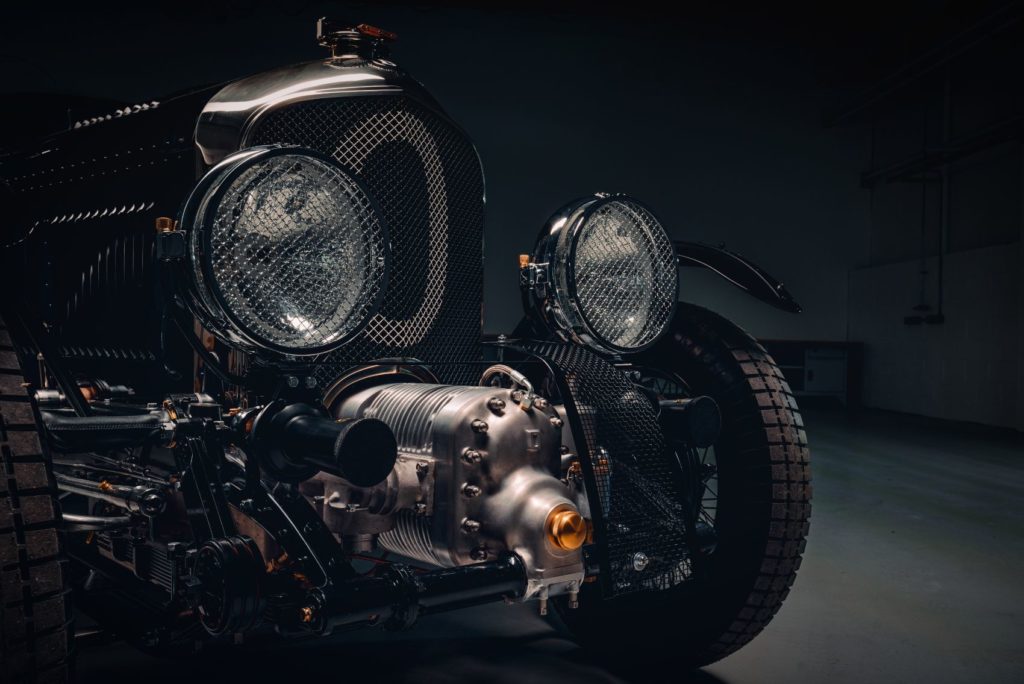

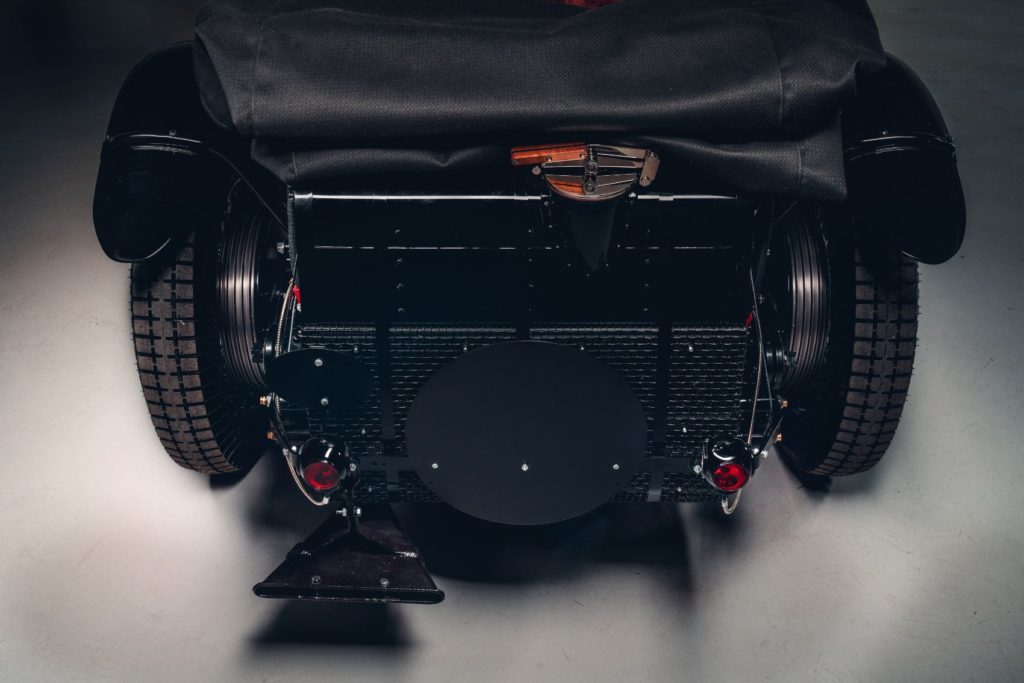

It is crafted from the original design drawings and uses the same tooling jigs for the original four Blowers built and raced by Birkin. Bentley’s own Team Car served as the master model for the Continuation Series, with every single component laser-scanned as part of a “from the wheels up” restoration.

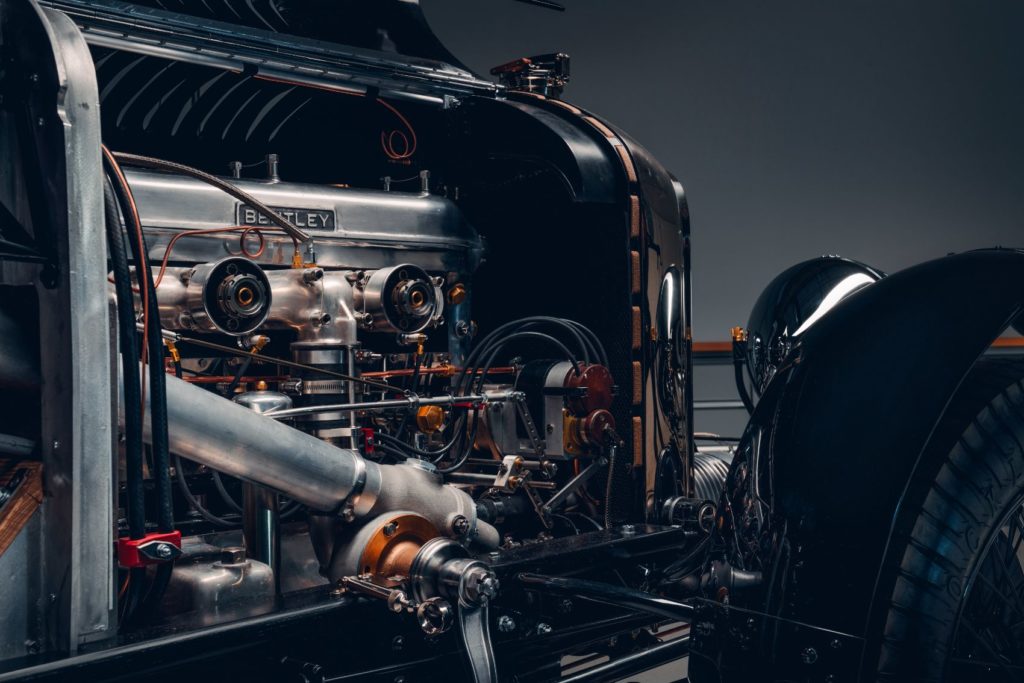

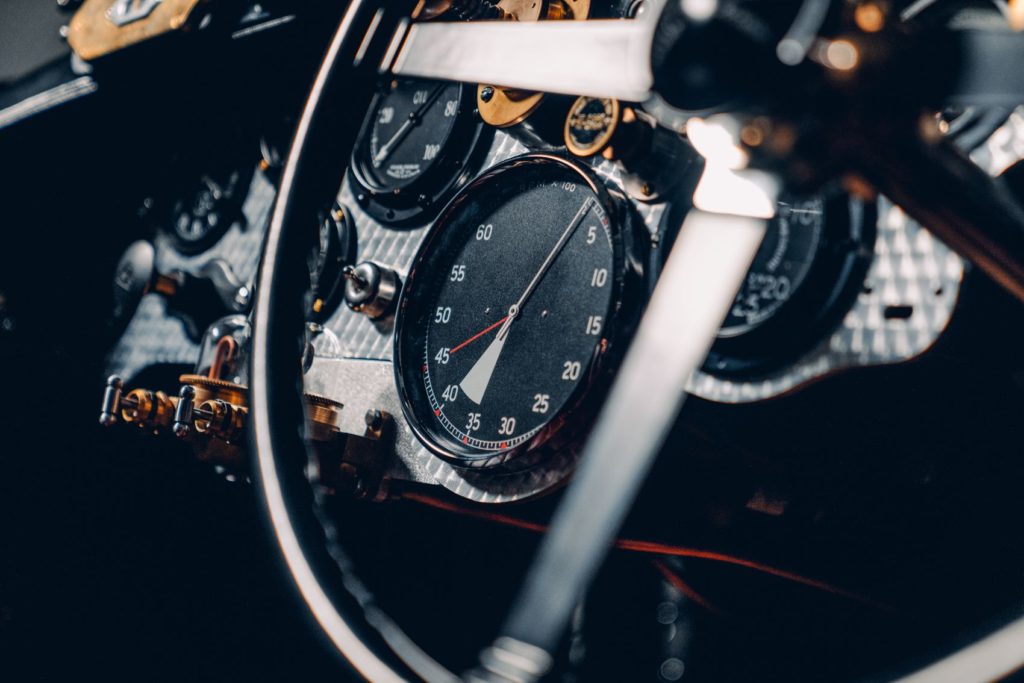

“The very latest digital design techniques came together with genuine artisanal hand-crafted artistry – often using manufacturing methods true to the 1920s,” explained Bentley’s Director of Mulliner, Paul Williams. “It’s only through this fusion of old and new that we could craft these cars, with the skills of our engineers mirrored in those of our specialist suppliers.”

Teamwork Makes The Dream Work

From the laser scanned data, 1,846 individual parts were designed and handcrafted to create the “new” Blower. Each of these parts and assemblies was created by a project team of Bentley Mulliner engineers, craftspeople, and technicians working together with other British specialists and suppliers. “We’ve issued thousands of drawings and specifications for components, and watching them arrive into Mulliner and then seeing the car take shape has been hugely rewarding,” Williams continued.

For example, the chassis has been forged in heavy-gauge steel, hand-formed and hot riveted by Israel Newton & Sons Ltd. The Vintage Car Radiator Company, based at Bicester Heritage, has crafted exact recreations of some of the Blower’s key components – including the mirror-polished, solid nickel silver radiator shell and the hand-beaten fuel tank formed in steel and copper. The leaf springs and shackles have been made to original specifications by Jones Springs Ltd, a specialist in the West Midlands.

And finally, the building of the new 4½-liter engine, originally designed by W.O Bentley, was done so under the supervision of NDR Ltd in Watford.

Car Zero: Extensive Testing & Development

After all of that, Blower Car Zero is still just a factory test and development prototype and will be subjected to months of durability and performance testing. Unlike every other pre-production prototype I’ve ever seen, Car Zero looks fantastic. They are finished in gloss black, with an interior in Oxblood red leather from Bridge of Weir. Just like the original cars, the new Blower’s seats are stuffed with 22 lbs. of natural horsehair.

Now that Car Zero has been rolled out, the next step will be a program of real-world durability testing. And Bentley isn’t joking around with a series of top speed tests to check functionality and durability under ever more demanding conditions. The test program is designed to achieve the equivalent of nearly 22,000 miles of real-world driving, including nearly 5,000 miles of track driving. The track driving will mirror rallies such as Peking to Paris and Mille Miglia.

“Now we start the next phase,” Williams said. “Testing and development, ahead of the build of the 12 customer cars.”

And I love this bit from Bentley corporate: “The testing will also see a particularly brave driver taking the car to its top speed – with Adrian Hallmark first in the queue…”

Adrian Hallmark, in case you’re wondering, is the CEO of Bentley. You gotta love a car company where the main man is in charge of details like this.

Longtime Automoblog writer Tony Borroz has worked on popular driving games as a content expert, in addition to working for aerospace companies, software giants, and as a movie stuntman. He lives in the northeast corner of the northwestern-most part of the Pacific Northwest.

Car Zero Gallery

Photos & Source: Bentley Motors.